Just about all of my prints have these lines at around the same heights, and I can’t figure out why. I tried changing the nozzle, changing the layer height from 0.15 to 0.12, and changing the speed from 60mm to 40mm. All of these seemed to have helped a bit, yet they remain. I was thinking maybe as the prints get to a certain height, the shaking of the bed (Prusa MK2) caused the layers to be slightly offset perhaps. Anyone have any other ideas?

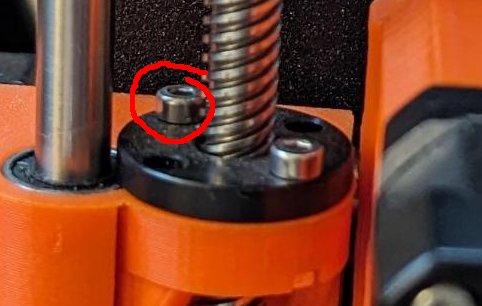

The fact the lines are at the same height between different jobs suggests something is wrong with your Z axis. Can you post photos of your printer, including the Z rails and/or screws?

Sorry for the late reply, tied up. Thankyou for the photos.

The Z-axis leadscrews look OK in the photos (nothing obviously wrong). That’s a very clean and new printer.

Q1. Is there any grease on those Z-axis leadscrews (tall metal spiral rods) or are they completely dry?

Q2. If you force your printer to move up and down does it make unusual noises at some parts of its travel height? You can try typing thing g-code into your printer monitor software to make it move up and down:

G0 Z100 F1000 (move to Z position 100mm. You won't actually travel at 1000mm/minute, instead the printer will do whatever it's max is) G0 Z0 F1000 (move to Z position 0mm, ie nozzle touching the bed)You may need to home the axes first (G28)

Q3. Are these screws on both sides properly tight? I think I might possibly see a gap under one, but it could also be an optical illusion from reflections.

Horizontal banding can be caused by a few things

- the slicer making the nozzle move differently between layers because there are different features in different layers. You can usually see this in the sliced gcode preview with something like nozzle speed

- inconsistent extrusion due to variation in hot end temp and/or filament width

- lead screw wobble. This will show up as a repeatable pattern along the z axis

- binding in the z-axis

- something loose, most likely on your gantry

If you print two different models and it happens at the same z height you can basically guarantee it’s a mechanical issue. If it’s more random you’ll need to troubleshoot further.

inconsistent extrusion due to variation in hot end temp and/or filament width

Also, a moist filament.

Check the Y and X axis for dirt or imperfection, thight all the screws and be sure the printer sits on a stable base.