Overzeetop

- 2 Posts

- 31 Comments

2·2 years ago

2·2 years agoIt’s been a little while, but they gutted the mesh editing tools in he free version. They also dropped the number of active models, restricted certain file-functions (maybe assemblies…I don’t do any/many), and limited file import/export.

1·2 years ago

1·2 years agoIt appears to be built specifically for designing electronics enclosures with 3D printing in mind. I’m sure it’s a great utility, and I don’t mean to argue to no end, but to me a tool built specifically for 3D printed design would have core functionality which offers layer line alignment and orientation, custom and customizable internal structure (what we call “fill”), and a parametric engine to adjust the design and internal structure based on layer and nozzle thickness. While these are all currently slicer-like functions, slicers are absolute trash at being able to customize a part for strength, stiffness, and failure mode selection. (Yes, I’m a structural engineer - I actually do know about these things and design for them - usually being at odds with the slicer over just such effects)

Anyway - I’m sure Dune3D comes in handy for its designer’s purpose, and I’ll probably file this for the next time I think about fighting a Pi case in CAD.

991·2 years ago

991·2 years agoNo, no - they’re not raising the price; they’re rebalancing it to reflect the value it delivers!!1!

And since they’ve reduced the free version functionality significantly, I believe I’m due a substantial rebate.

4·2 years ago

4·2 years agoI mean you could always switch to Bentley. AFAICT, they’re actually more Byzantine in their licensing structure, though. They bought a small analysis program company I used and their support was so terrible I gave up and learned a whole new FEM program rather than continue.

2·2 years ago

2·2 years agoI’ve been through the donut tutorial. Is there a CAD sketching / exact dimension /parametric modeling interface buried somewhere in Blender?

61·2 years ago

61·2 years agoI agree it’s a silly breakpoint, but they have to draw the line somewhere, and I’m sure they feel that a 70/30 split is completely reasonable. Besides, a Fusion license is practically coins-in-the-couch compared to their architectural licensing fees. I’m sure they feel like they’re doing us a favor by pricing Fusion so low.

2·2 years ago

2·2 years agoI don’t; at least no in our lifetimes (I’ll call that 50 years). I’ve been an engineer in the building industry for 25 of my 35 professional years, and I’ve watched multiple “disruptive” technologies progress and mature. 3D printing may very well become a useful tool for complex building geometry in certain niche markets but it will not take over any substantial part of the building industry during the life of any adult today. And I say that as someone who has helped new technologies to market, done design for nearly every (non-3d printed) material around (cordwood, straw, timbercrete - hell, I had a guy call me who wanted to build a garage out of 400 surplus 19" aluminum server racks he got at an auction).

3D printed walls will go right up there with geodesic domes, hyperbolic parabaloid concrete, and (as much as I hate to say it) structural insulated panels. It’s not that there is anything wrong with it, or the other methods I mention, it will simply not achieve mass adoption due to a combination of appearance and cost competitiveness of the finished product.

82·2 years ago

82·2 years agoIf all of your relationships end because of animosity between you and your partner, it may not be that your partners are the difficult ones.

1·2 years ago

1·2 years agoNormally, I would agree. For a teen living at home and (based on the price range) without a dedicated space, I think it’s the preferable of the two options. Having known someone severely burned by an errant spark around IPA, and with the added complications of disposing of contaminated IPA, waterborne is the lesser of evils. I 100% agree that I should have pointed out that “water washable” doesn’t mean rinse/clean off in a sink that leads to a private septic or public treatment system.

20·2 years ago

20·2 years agoim looking into making mini figures and painting them

Boom, right there should limit your section to SLA/resin printers, not FDM as most people here are suggesting. At $100 budget you’re down in the absolute basement of printers, and will have to find a machine on sale. Good news for you is that this is the month of sales (Black Friday month). You are looking at either an Anycubic Mono (out of production, I think) or Mono 2 when they go on sale, or mayby an Elegoo Mars - I’d expect to see it between $99-119 sometime this month. (there’s a monoprice mini SLA printer for $70 out there, but I don’t know how good it is)

There are two things to know about resin: the liquid used is toxic, so someplace with ventilation and a supply of cheap latex/vinyl/nitrile gloves are a must, as is a workspace which can be easily cleaned (they sell silicone mats…its a good idea; you might try ordering misc stuff from TEMU for your accessory list to save some cash) and a roll of paper towels is going to be necessary. The second is that standard resin requires 95% or higher isopropyl alcohol (IPA) to clean the prints, and to clean up the machine parts. That can get expensive, too - so SKIP IT and get Water Washable resin. It will cost more, but the ease (and lower odor) in clean up will be worth it, especially if your parents would rather you not be slinging flammable IPA around the house.

You do NOT need a dedicated wash and curing station. It’s a luxury you can’t afford, so just skip it (for now). There are lots of videos about how to clean parts using a two-bin or three-bin method and they just use cheap dollar-store plastic bins or used buckets (do not use tupperware you eat from…water washable is still toxic, okay?). Then, just set your prints in the sun for a few minutes - it even works on a cloudy day (clouds only block a fraction of UV).

You should be able to make table-top sized miniatures for painting in one go, or make them as two or three parts for bigger models. The detail you get out of an SLA printer will be worlds better than an FDM (extrusion) printer and require a lot less sanding, filling, and misc post-processing prior to painting.

Quick edit: @QuietStorm@lemm.ee - Creality is also having a sale this month and there are two SLA printers on sale in the $99 range. The nicer (bigger) one is currently out of stock, but you might check back and see if it comes back in. Nearly all of the small SLA printers in this range are very similar, though you should read up in their forums just to see if there are some crazy problems everyone is having with a specific model (no news is probably good news).

2·2 years ago

2·2 years agoAll indications point to Apple restricting background timeslices for programs to reduce available compute cycles. Keeping modern chips at top speed for processing in bursts and then sleeping is actually more power efficient than throttling and allowing continuous calculation ( https://en.wikichip.org/wiki/race-to-sleep ) At nominal TDP, the A17 will drain an iPhone 15 battery from 100% to 0% in under 3-4 hours, even with the radios and screen off. The only way it can usefully function is to be in sleep mode most of the time and some processes were getting more time slices than would allow that.

2·2 years ago

2·2 years agoUnless it’s a hardware failure causing spurious emission, it just means that transmit power has been reduced in software. Practically, this will reduce the range at which you can communicate to the cell tower. The cell tower reception should remain nominally the the same strength and the same speed, but you will have a reduce range for towers to which you can reliably connect (i.e. dropped connections) because you can’t tell the tower you’re listening. Also, your upload throughput will be lower at a given distance from the tower as your distance from the tower increases beyond a (now smaller) full-connection-strength radius.

3·2 years ago

3·2 years agoNot every adventure goes as planned. Those that don’t usually end up with a great story!

5·2 years ago

5·2 years agoY’all can be all high and mighty about it, but if I saw $750 sitting on top of a pile of outhouse poo, you can bet I’m gonna be willing to come out with blue goop up to my wrist.

11·2 years ago

11·2 years agoI’d be curious what their measure of concrete is. The plain stuff has 3000psi compressive strength and a usable modulus of rupture of around 250psi. And if it survives re-wetting / over-drying and aging.

PLA is (very) roughly 20x that.

5·2 years ago

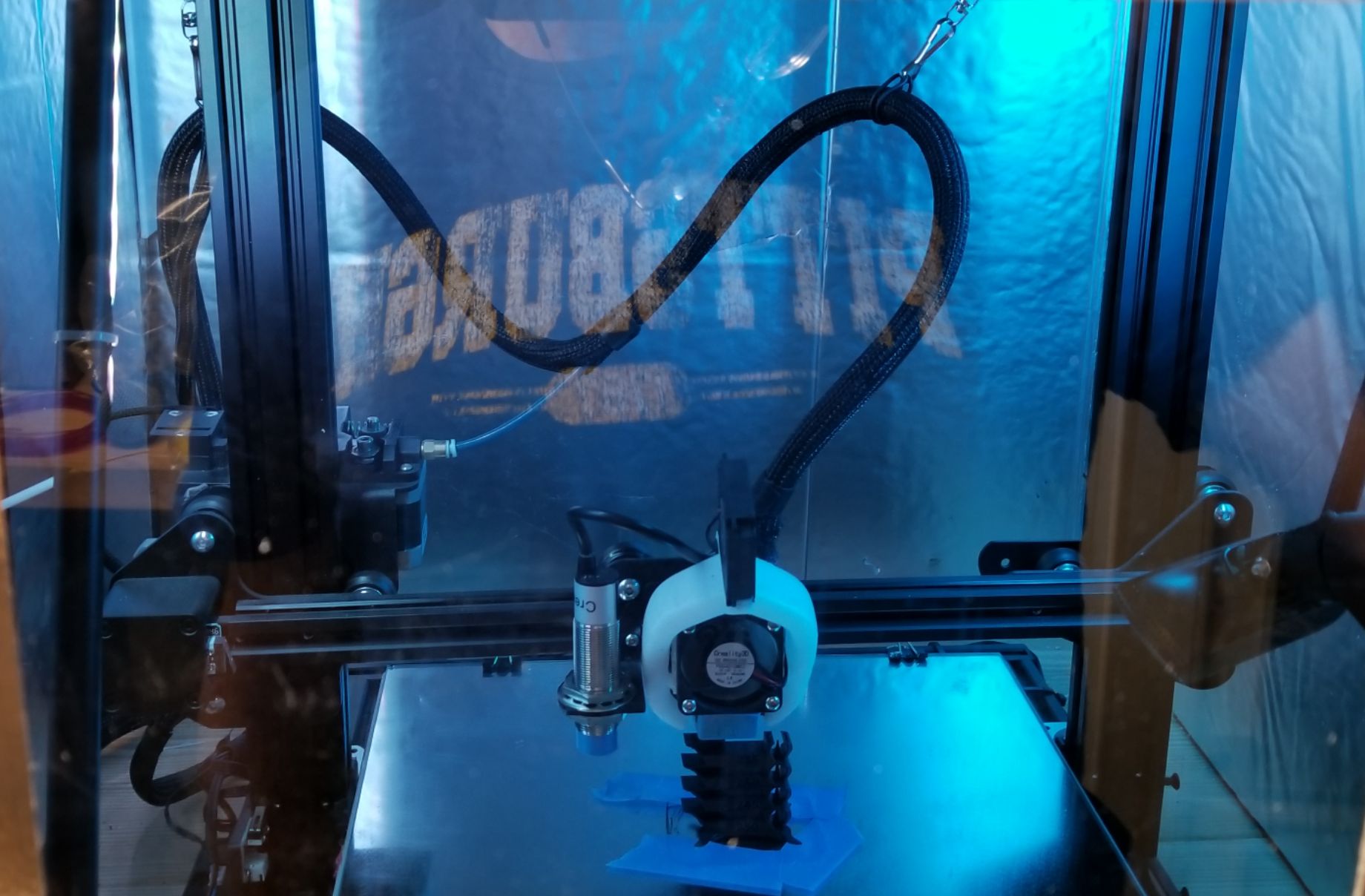

5·2 years agoThis is exactly what I do. I had a couple retractable cables let over from my wired-VR days and rigged it up on my CR10s. Works great. Here’s a pic - they tops are just connected to the top rail with a rubber band for easy removal. (this was take through the “window” in my enclosure, so you can’t see the top)

9·2 years ago

9·2 years agoBluetooth is a dumpster fire

Hard to argue with that.

5·2 years ago

5·2 years agoYes, but will they sell replacement cases with USB-C for existing users. Ideally for less than it costs to buy an entirely new pair of buds with the C case.

3·2 years ago

3·2 years ago90% of the experience is great. 10% of the experience is wondering why anyone sane would choose the UI or functionality as the default method and not provide any way to alter it. If you’re someone who wastes time on setting up your UI just the way you like it, consider it a bonus that you get that time back.

Oh, and if you get an LTE AppleWatch to go with it, the watch will occasionally “forget” that it has a plan and silently switch to bluetooth only - and can’t be re-enabled on the LTE network without the phone. Not that I’m bitter about that time it happened when I didn’t have my phone and I got stranded.

If this was during an auto level, it’s my humble opinion that this is a manufacturer’s defect in the machine that caused the damage. There should be proper coding to ensure that any increase in sensor pressure by (delta p) halt that machine and that there should be a pressure offset in the sensor such that a loss of signal or anomalous zero reading or lack of reading is done prior to levelling to ensure that a sensor failure has not occurred. My XL freaks out if a fan isn’t spinning at the right speed, so they clearly know that a nominal operational check before the print starts is proper engineering design.

Of course you won’t get anywhere. Unfortunately, a lot of 3D print failures really are user error so I suspect that’s their default response and it takes them a good deal of proof to push them of that mark.