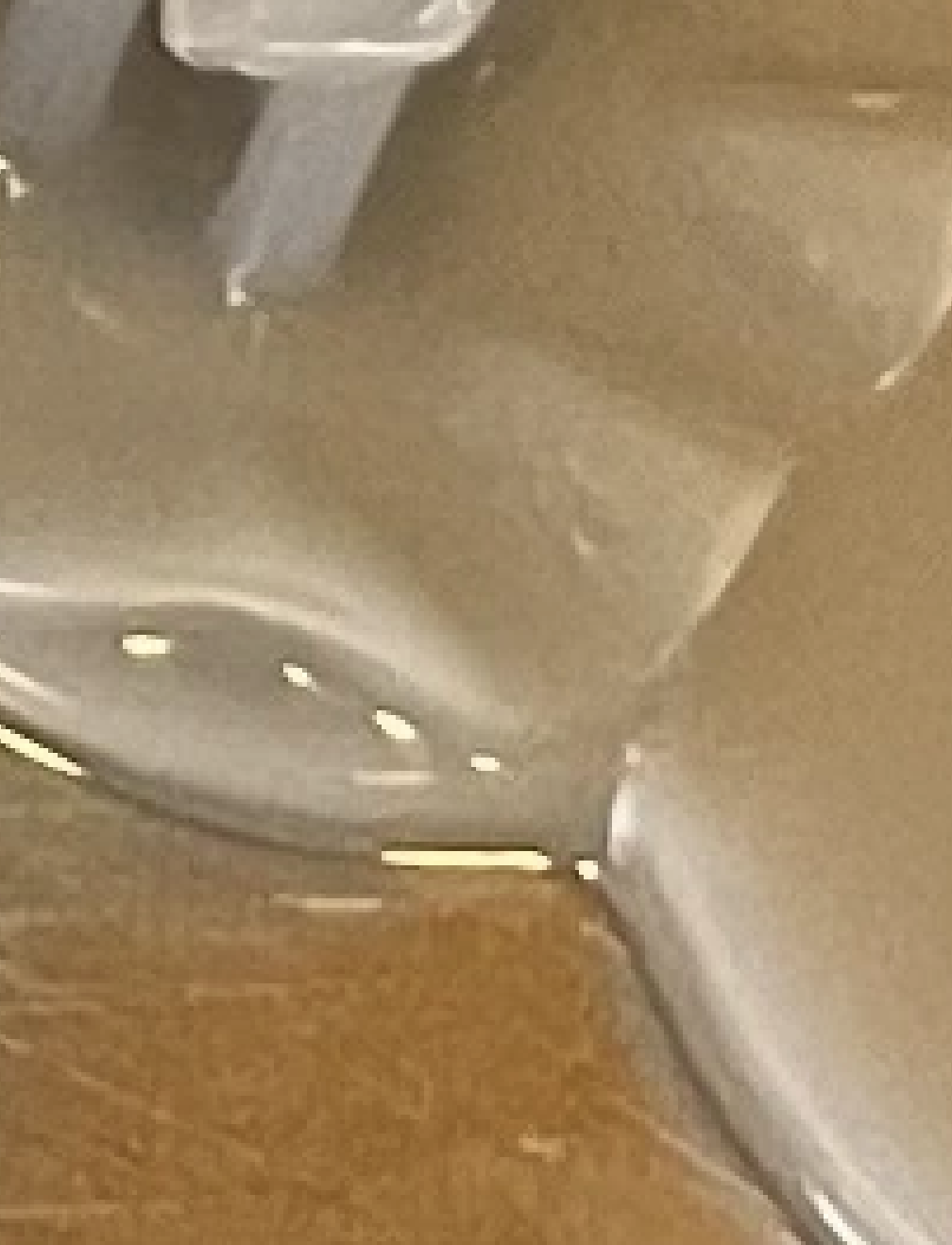

I don’t resin print, but it looks like there is a missing layer or two. The ripples in the interface layers at the bed were confusing me at first, but that seems like it they were formed in the resin not being attached to anything. The rest of the print is failing at the same layers of those strange ripples.

My guess would be a mechanical issue with the main Z screw, like there is something in that part of the thread that is causing it to lift a bit higher than it should. If it was completely loose, the rest of the print wouldn’t be viable.

Clean the threads of the screw and try to replicate that error at those layers with a test print. Isolate the problem, is my advice.

This part is really funky:

Just isolate the problem, is the rule of thumb. If you can replicate the issue reliably, it’s fixable. At worst, it limits the number of variables you are working with, which is still awesome in its own way.

My only other thought would be a bizarre stepper motor skip, which would lead me to start checking wiring and such.