Huh, I never had crashes.

Even with an Edu License for Autodesk, I HATE the UI.

Huh, I never had crashes.

Even with an Edu License for Autodesk, I HATE the UI.

I’m sticking to FreeCAD.

A foss buildable car sounds cool.

I don’t exacly know what you mean, but the (generic) Form Factor of this device is:

The device is rain-resistant, but nothing fancy.

It’s wall powered.

It doesn’t use LAN/PAM. Instead, a local config and IR controller is used to modify paramaters. However, you could code this in.

Sould there be anything to change for the device?

Yes.

A custom soil moisture sensor was used.

A seperate config file wasn’t used, but there is a controller able to change the config.

The box monitors temp/humidity and soil moisture and Beeps/Flashes to inform that the plant needs maintenance.

Yes.

With PLA, you can submerge your part with sand and use molten metal. (PLA Casting)

3D printer can also print metals. You just need a special nozzle and metal fillament.

The entire device should be 3d metal printed.

If you want a lighter device. Plastic works on:

Metal is needed on:

A tiny nudge will be applied since the ring guard passes the computer’s casing. Thicker computers won’t have this issue.

Some propping may be needed since the lock is quite large.

Unfortunely, I can’t real-world test since I don’t have a printer. But FEM tells me that this device does well aganst torque (Aluminum). Pulling/Yanking is good too.

Give it a try, Axiochus! ;) A test plate is provided.

Firstly, these are open-source for community improvement.

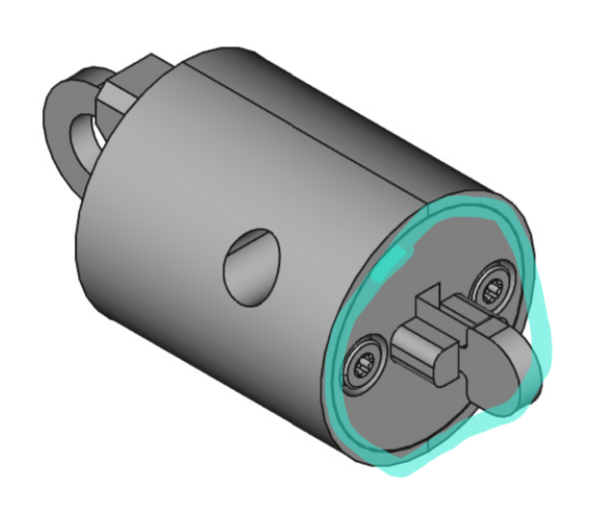

bending/tampering resistance by the use of guards.

Front guard disallows the shackle from being bent.

The Back guard protects the back shackle from bending.

The ring guard protects tampering of the guards.

(This info below may be inaccurate since I changed partial lock design. FEM testing wasn’t used right now.)

The shackle is designed to withstand 2-7k netwons. (2k when aluminum is used, 7k if steel is used.)

(This was found on the web. This may be mild/severly innacurate. Take this with a grain of salt.)

~200 Newtons are required to move a car.

Also the shackle tip is round instead of square. This improves the shackle from V-bending:

Kensington Shakle tip: ====[]

My shakle tip: ====D

(Don’t throw out of context… :|)

And finally, it’s cheap and easy to make.

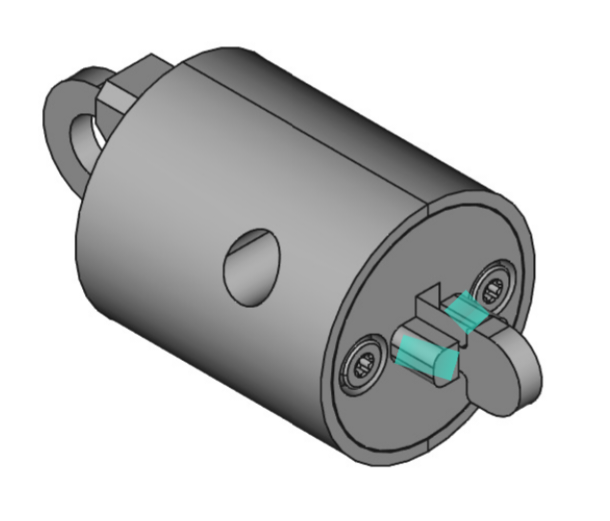

This is a lock to anchor your device to something.

If you have a laptop/desktop. Look to the side and you will see a Rectangle

This lock uses that hole and this will anchor the device. (Just need a cable.)

The offical K-Lock used by kensington are these.

Get it?

Is it MakerBot or TakerBot?

Ok

I’ll go with STEP.

Thanks.

Alright, STEP it is.

Once it gets better, I may try it.

I’ll include the software (FreeCAD 0.20.2) for compatibility.

Although, my files work fine on 0.21, I’ll add that just in case.

Sorry. What is the diffrence between STEP and STL? I thought STL was preffered.

Try the latest appimage. I use thoses.