NaibofTabr

- 1 Post

- 42 Comments

3·2 years ago

3·2 years agoHow fast are you trying to print? Does it behave differently if you slow down?

One of the reasons prints can shrink like this is that the speed is essentially stretching the plastic as it comes out the nozzle, like a rubber band. As the plastic settles that tension pulls it together.

I doubt moisture is the issue, PLA doesn’t actually absorb water very quickly.

Also, have you done a temperature tower and flow calibrarion for this filament?

4·2 years ago

4·2 years agoMore rentals = more demand = more copies purchased by rental stores (I can’t rent you the game you want if someone else has it right now).

17·2 years ago

17·2 years agoProbably some games did after the home rental market got started, but a lot of older games were difficult specifically to extend the experience. Cartridge storage was small, so if it was too easy you’d get through all 10 levels in less than a day and then feel like you hadn’t got very much for your money.

24·2 years ago

24·2 years ago

231·2 years ago

231·2 years agoMaybe not completely a gimmick - you can actually build functional walls with it. But it is nowhere near replacing traditional construction in terms of cost or time.

Personally, I don’t see this process ever getting easier. Concrete pumping is a nasty, complicated and error-prone business. Once you mix concrete it is immediately starting to cure - you have a very limited amount of time before it turns into rock inside the printer. Just think about trying to pump a thick fluid with the density of stone - every part of the system is always on the edge of clogging up. It’s an impressive technical feat that any of these projects actually completed their walls, but none of the advertising videos are showing you how much micromanagement is being done to keep the printers working.

162·2 years ago

162·2 years agohaving the potential to be significantly cheaper and faster than standard construction

I don’t see how this can ever be true. The only material that can come out of the printer is the concrete for the walls. The walls then have to be reinforced (because concrete is only good under compression), insulated, finished, and then have windows, doors, wiring and plumbing installed… all of which is still just manual labor. The walls aren’t even the expensive part of homebuilding.

15·2 years ago

15·2 years ago

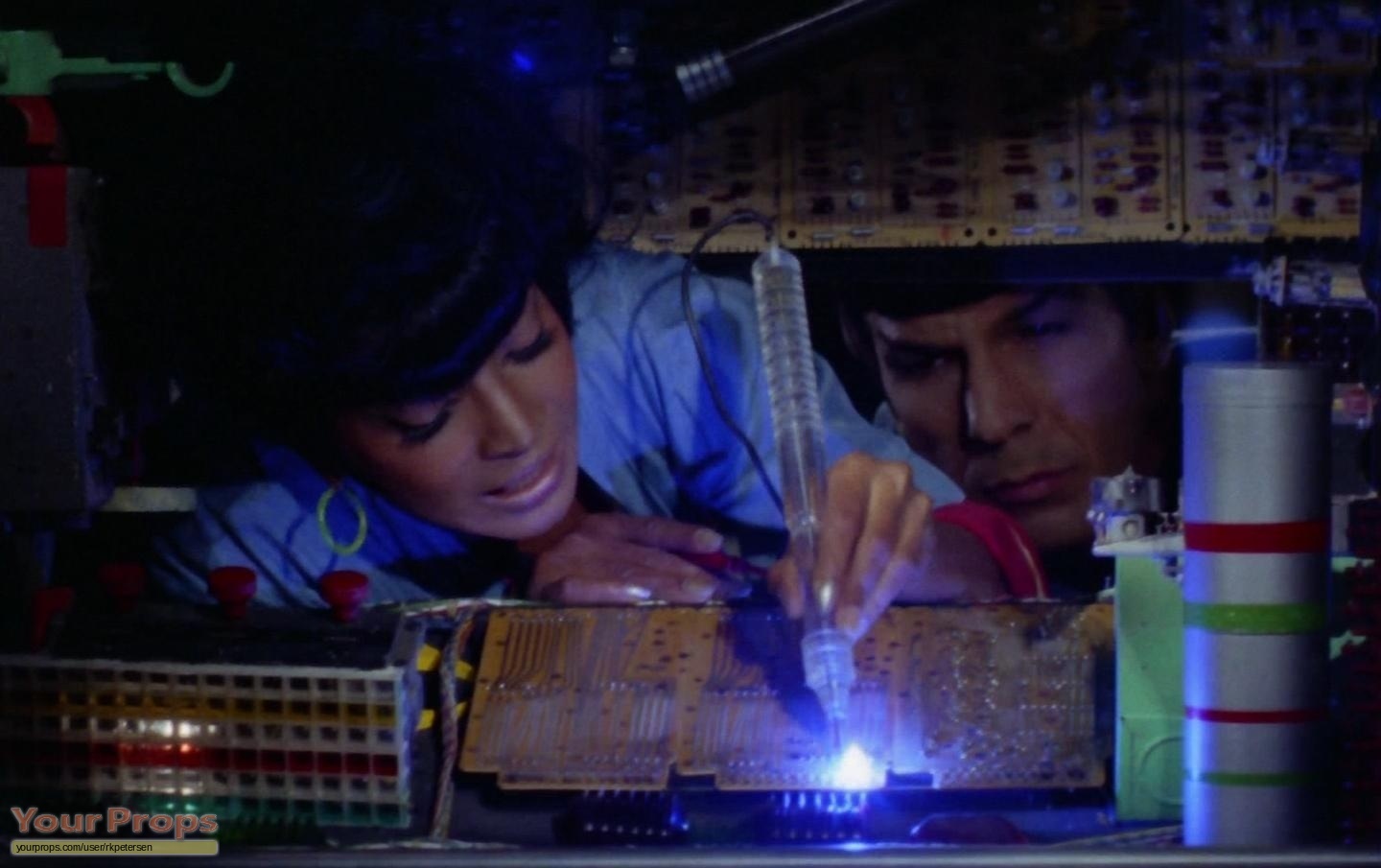

Some real dense, high-tech circuitry going on in there…

…is that an isolinear rod next to Uhura’s head?

How would the Tamarians ever develop any advanced technology? Can you imagine an engineering discussion in Tamarian? Like, what is the word for capacitor? “Edward, when he enclosed conductive foil and electrolyte in a metal cylinder”? What would a Tamarian technical manual even look like?

Are you printing this near the center of your print bed?

I suspect that the object is not fully peeling off the FEP film, but just pulling it up for some of the layers. When it eventually releases the print continues.

I think you should lift higher, maybe double it to 10mm, to make sure that it completely separates from the film every layer.

CoreXY has advantages over the typical RepRap-style 3-axis movement or bed-slingers. The frame is more rigid, so the print head can move faster while maintaining accuracy. The enclosure also lets you print higher temp materials with less warping.

I’ve been looking at getting something new in this range also, and found the Kingroon KLP1, which is a fully enclosed Core XY design.

Just enjoy the gritty crunch that tastes just like chicken

8·2 years ago

8·2 years agoWell he’s definitely not in engineering.

1·2 years ago

1·2 years agoHave you used this same filament from this manufacturer before and had different results?

Polymer blends vary wildly between manufacturers and there are all kinds of additives used to adjust the thermal & mechanical properties of the material. Even the dye used can affect the way the plastic behaves. Most PLA filaments on the market are not actually 100% PLA because the resulting products tend to be brittle and fragile, so various adjusted PLA blends have become more popular. There are a lot of options for plasticizers that can be added, and there is absolutely no standardization between manufacturers of which ones get used or in what ratios they are added to the base PLA.

I haven’t shown them, but I did print a temp tower and retraction tower when I first got the printer, which is how I got my initial 190deg, 4.5mm@40mm/s settings

This is not really good enough. Every material is different, even the same PLA blend from the same manufacturer but in a different color might need different settings to get good results.

Right, ok, so I’m not particularly familiar with Cura… I use SuperSlicer which is a fork of Prusa (which is a fork of Slic3r). Neither slicer has a UI option for initial purge lines as far as I can tell.

So for both Prusa and Cura you are using a block of custom start gcode to define the purge lines? Exactly the same gcode in both slicers?

Could you please share the Cura gcode output in addition to the Prusa version you shared? I am curious what the difference is.

That is interesting. Does CuraSlicer do the same priming lines? Have you tried the print with PrusaSlicer without the priming lines?

If you can figure out what Cura is doing differently in that section of the gcode you could put those lines in the custom gcode box in PrusaSlicer and get the same results.

The first two ads I see under the article are for hearing aids, which probably describes the target market for this thing.