Hope it goes well!

Hope it goes well!

The only thing I can think of with the extruder is thermal runaway, but Klipper would tell you if that was the case. Have you tried with no camera plugged in? If new USB cables aren’t working, it might be worth starting from scratch and rebuilding your Klipper instances. If a clean Klipper install (with no webcams or anything) is breaking, then it’s likely going to be a hardware issue.

How old is your Pi? I had the same issues on a generic board (Le Potato) but upgrading to a Pi 4 Model B fixed it for me. I have both my Neptune 2S (modded) and Neptune 3 Pro (stock) running on the same Pi with no issues.

Definitely change your USB cable. If you’ve got some complex files, maybe the cable can’t handle the bandwidth (experienced this back when I was first starting out)

Lots of different ways to get into it. I personally love my Elegoo printers (An older Neptune 2S and a Neptune 3 Pro)

Need to do one of those speed/acceleration calibrations myself. I’ve reduced my speed for better quality, but it’d be fun to know my limits

Check out the AAWireless dongle. It’s mainly for Android, but its beta version seems to have CarPlay support.

Tried IID Max’s PLA+ since they were always posting discounts on Reddit. I’ve stuck with them since for anything that needs color, their filament is vibrant and I’ve never had any issues. Buying in bulk you’re looking at roughly $10/kg. For my black I use Elegoo PLA. It has a nice sheen to it.

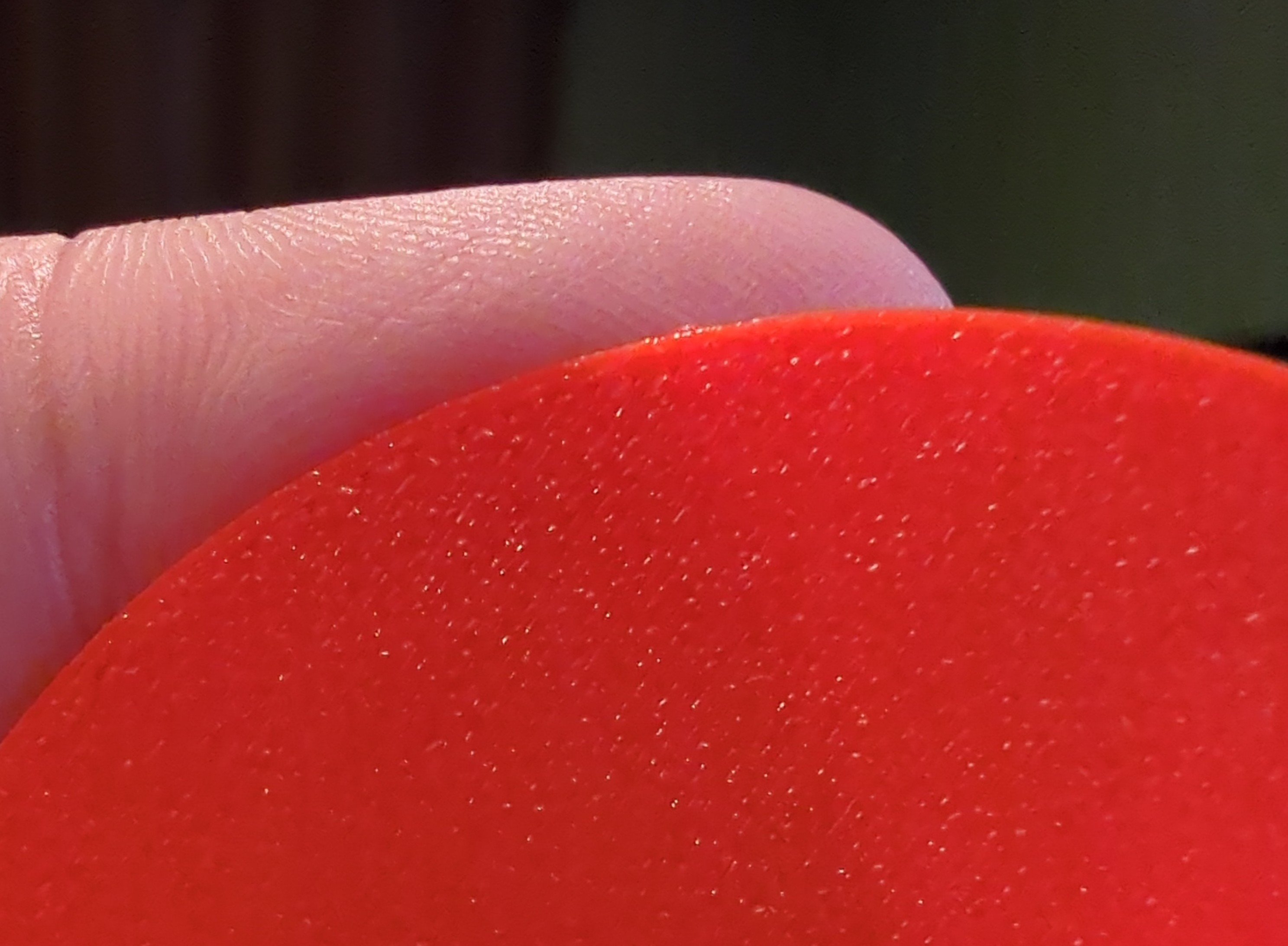

It’s actually orange! But yeah, super vibrant. My favorite brand is IIID Max, their PLA+ is very vibrant

Just ran a disk like yours as comparison. You have to look pretty close to see the individual lines!

If that’s the 1st layer we’re looking at, you can get even closer. You want all those lines to be merged with each other.

Printing the 1st layer slow is so important, forgot about that! I’m down to 25mm/s on my first layer. Nice and slow. A print with a large surface area (Like a sign) may take 15 minutes on the 1st layer, but it’s definitely worth it.

Going by just the failed circular print, you definitely don’t have a good Z offset. There’s no smoosh there. Putting it lower will smoosh the filament into the print bed (Part of why the PEI sheet is textured. The filament smooshed in the texture helps hold it better than a flat print bed). The fact that you can see through your first layer is bad.

The top layers of your other failed prints look good, so I say we can rule out under/over-extrusion.

The humidity issue IMO is often overblown. It’s really environment specific. In my old place my relative humidity was 35% so wet filament was never a problem. It’d be good to get a hygrometer to see where you’re at before you start buying fancy filament dryers or accidentally melting your spools in the oven. If your area is generally high humidity then it can help. With PLA though it’s not going to make a huge difference.

Printing really is fun! But there’s so much to troubleshoot, it’s a time sink to get things right. My 2nd printer is down from a dead fan, one of these days I need to solder the broken wire back on.

But once your printer is tuned, oh boy it’s satisfying

Oh this for sure. Sharp corners? Brim. Tall print? Brim. Small contact area on the bed? You won’t believe it, but brim.

Hard to know what’s going on without pictures. Could be any number of things. My first thought is over-extrusion if the nozzle is catching your print and knocking it over. Or maybe you need Z hop between layers. I’ve only used Prusaslicer so can’t say what to do to help in Cura. If you’ve completely replaced the hot end, you should be re-tuning your printer (PID tuning for correct temps, e-steps for correct extrusion amounts, etc). If it’s adhesion problems where the print isn’t sticking to the bed, applying some glue stick can help keep things secure.

The top looks 3D printed. Maybe they made a new cover?

Here’s the retraction calibration test I use http://retractioncalibration.com/

Printed at 200% (So 200mm tall in total). 195mm was just that layer’s height. Who knows what little setting was making it be like that.

Do you have another printer to test with? Maybe it’s something in the SKR Mini that’s not working.